DSA Acoustic Door Seal Testing

A series of comprehensive tests to establish the airborne sound insulation performance of DSA acoustic

seals have been conducted in accordance with: AS1191 / ISO 140-3 / EN ISO 10140.

How DSA Test for Acoustic Sealing Performance

DSA sealing systems are acoustically tested in their normal everyday operational mode under laboratory

conditions. To evaluate the door assembly acoustic efficiency, DSA conduct a series of three tests:

No Seals – A test with the gaps around a door unsealed, also known as uncaulked. This provides the minimum level of performance a door can achieve with no seals.

With DSA Seals – The same door is fitted with DSA seals around the full perimeter and re-tested to determine the acoustic performance improvement.

Fully Caulked – The gaps around the door perimeter are sealed with a high density acoustic putty and retested to determine the maximum possible acoustic performance of the door assembly.

By comparing these three test results it is possible to determine and rate the sealing system efficiency and maximum potential performance of a door assembly under evaluation.

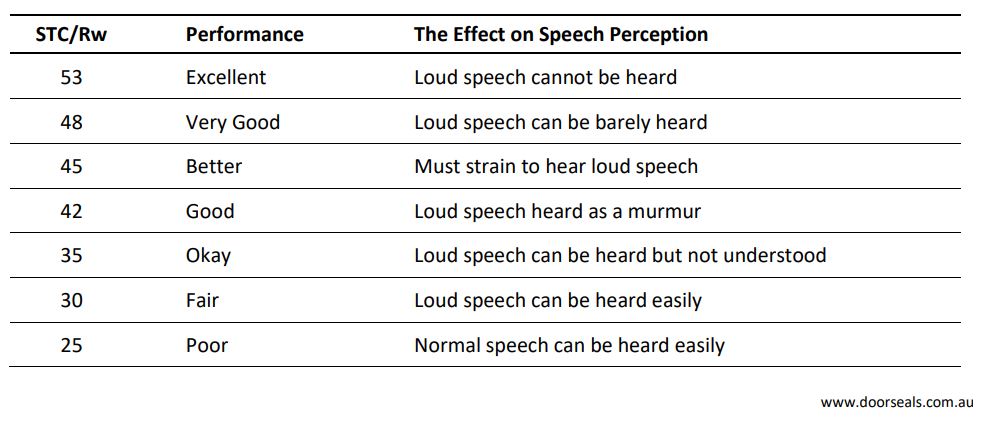

These Rating Systems are used to Measure Acoustic Seal System Performance

STC – Sound Transmission Class

The noise performance of a building structure is called the Sound Transmission Class (STC). It is calculated

from 1/3 octave band sound transmission loss data by a method described in American Society for Testing

Materials (ASTM E316). The higher the STC the better the structure is at isolating airborne noise. An STC

rating of 45 means that the sound passing through the building is reduced by 45dB.

Rw – Weighted Sound Reduction Index

Rw was developed by the International Standards Organisation (ISO), it uses a slightly different frequency

range (100-3150Hz versus 125-4000 Hz for STC). In general, STC or Rw give either the same rating result

number, or just only 1 to 2 points’ difference.